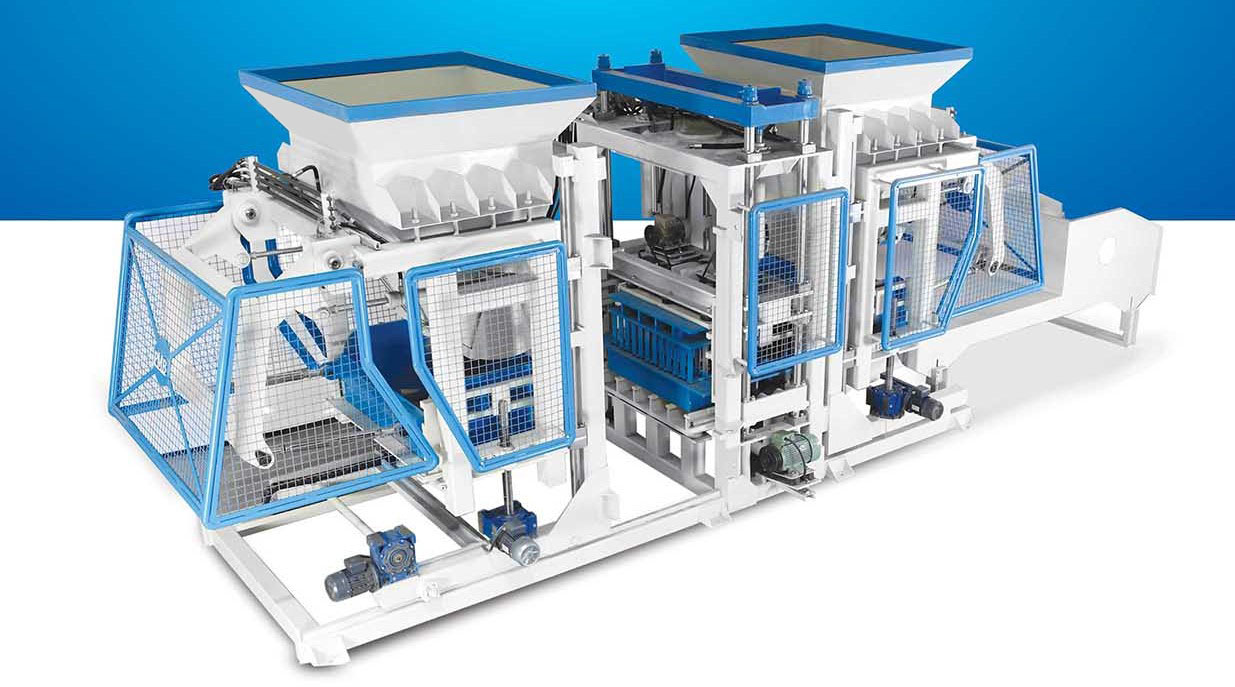

Automatic Concrete Block Machine TP.RN2025 is produced by Aradsan Machine. This system can produce different types of concrete parts such as curbstone, cement block, pavers and flower box. It is possible just by changing the mould.

The production line of TP.RN2025 full- automatic from the basic to advance phase (weighing material, mixing materials, production, curing system and packing) is done by machine and without human interposition.

According to advancement of science and technology, updated production of urban and industrial material and every day progress in concrete production, Aradsan Machine present it’s products to markets based on the internal and international standards.

The aim of producing the system is improving the quality of concrete parts, producing more products, reducing the labor and the production expenses.

Facing problems such as lack of experts, impossibility of quality control in traditional products because of lack of using well equipped laboratories and modern machinery for good concrete, lack of knowledge of materials used in traditional methods and other problems has made this company to design and manufacture machines capable of producing curbstone, block, pavers and flowerbox. The products of Parsian Machine with preservation of the quality and quantity of concrete production components and increasing the field of operation have succeeded in facing the needs of the community in the field of the competition with domestic and foreign competitors .

The system of TP.RN2025 is manufactured (basic to advanced parts) with equipment that is made in Italy or Germany. In fact, this principle will minimize the failure of the system so the life of the system is prolonged and it will cause to prevent from costly expenses.

THE SPECIFICATION OF PARTS USED IN TP.RN2025:

Pump’s generator: Siemens

Vibration’s generator: Siemens or Vem (Germany)

Electromotor for setting section: Deg

The piston jack’s tube: Boch or Bohler (Germany)

The integrated sheet for mould (paver) ck 45: heated sheet or Dillidur

Hydraulic hose: Flex (Germany or Italy)

All sheets of moulds are made from ST60 or ST52 and the parts exposed to the friction is manufactured with anti-friction steel (seven different sheet)

Jack’s shaft: Hard chrome (Italy)

Control panel: Plc, Siemens (Germany)

All parts of control panel: Siemens (Germany) with 15 inch touch screen.

Micro switch and sensors: Muller (Germany)

The cooling of oil system is done by radiator

The frame of machine: special profile with 12 mm thickness

The sheets used inside mixer: Hardox (Sweden), Dillidur (Germany)

Pallet Size 120*110